ABOUT US

Guangdong Hwashi Technology Inc. was established in 2001 whose

registered capital is RMB 10.309 million.

Hwashi has two production bases in Huizhou, Guangdong Province and

Gaoan, Jiangxi Province, covering

a total area of 50,000 square meters. Several branches were set up

in Hong Kong, Shenzhen, Shanghai,

Wenzhou, etc. Hwashi is the leading company in welding industry in

China and has been awarded the famous

brand for years. Hwashi welding machines are selling to more than

70 countries like areas in Russia, India,

Turkey, Chile, U.S. Saudi Arabia, Italy, Hungary, South Korea,

Japan, etc. for providing the best welding machine

and automation solution to the top companies all over the world.

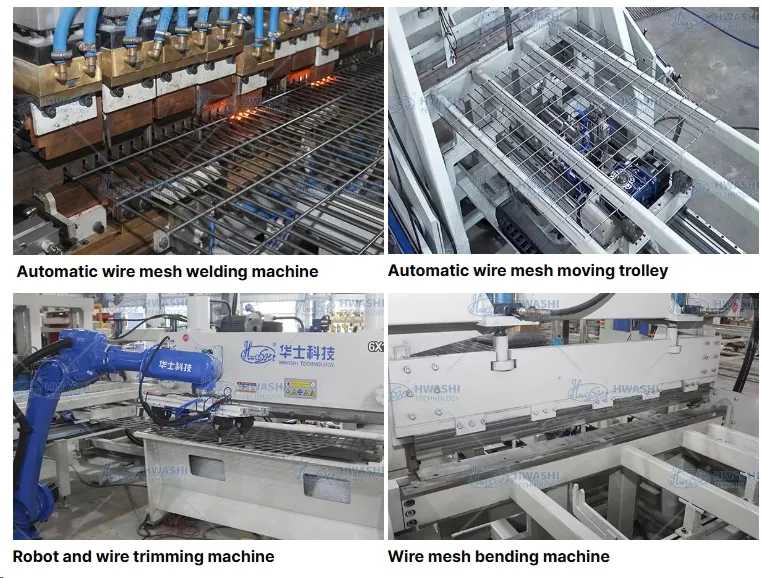

Hwashi company is a high-tech enterprise which is specialized in

developing, manufacturing and selling

of standard resistance welding machine, customized automatic

welding machine, and industrial robot, etc.

A professional and rich experienced technical team gathered in

Hwashi. They insist in self-developing

and take the overseas advanced technology as reference and has

obtained more than 70 national patents.

Except for the standard resistance welding machine, they also

devote in developing all kinds of automatic

welding machine and production line. Lots of automatic welding

production lines has been designed and

manufactured for famous companies in domestic and abroad

successfully. Hwashi equipment has

been widely applied to manufacturing industries like cookware,

automobile, motorcycle, hardware,

household appliances, low-voltage apparatus, elevator, compressor,

etc. In terms of quality, Hwashi has

obtained ISO9001:2000 certificate of quality system, CCC and CE

certificate. The main customers

include MIDEA Group, SUPOR Group, GREE Group, Shanghai Panasonic,

DELIXI, BYD, MEYER Thailand,

BRG India, etc.

"Caring for our customers and providing earnest service" is the aim

of Hwashi company. To meet what you

need is the goal Hwashi pursue. They are committed to become the

top class welding solution expert in the

world and break through all kinds of welding difficulties to create

real value for customers.

Professional Team

Over the years, Hwashi has cultivated a large number of talented,

dedicated and innovative Hwashi people.

We have a professional team of experts with rich experience in

electrical engineering, mechanical design and

welding technology.

FAQ:

Q1: what is the price of your machine?

Answer: our machines are customized for your requirements. If you

want to get the appropriate

price, please provide us the following information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product

drawings so our engineer can come out with

the suitable technical proposal and price for you.

Q2: what is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If

you want to extend the warranty period,

there will be extra cost.

Q3: what if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem

via online guidance. if any parts damaged

during the warranty period, we will send the parts to you for

replacement free of charge. If you can not fix he

problem by replacement of the new parts, we will send engineer to

your factory to help fixing the machine.

Q4: what is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our

standard machine we got in stock, then

we can shape the machine with the seven days after receiving your

payment. If you need the Customized

machine, normally it would take about 30-90 days to complete the

machine.

Q5: can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we

will send you the pictures and videos

after the testing. If you need, we can also send the samples back

to your country so you can check

the welding quality by yourself before ordering the machine.

Q6: can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product

drawings, our engineer will come out

with the suitable technical proposal with the basic machine concept drawings to you.

Be size after you

placing the order we will send you the more detailed design

drawings of the machine to you for confirmation.

Only after you confirming the drawings then we will start the

manufacturing process.

Q7: what’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C,

Western Union, Alibaba trade assurance.

(we prefer you to choose the Alibaba trade assurance order. If you

are not satisfied with the machine that

you order, or we delay the shipping time, then you can apply the

complaint on alibaba.com. )

Q8: how can we install the machine?

Answer: for some simple machines we will provide you the english

operation manual, the operation video

and also we will provide you the online guidance and training to

your engineer so you can set up the

machine easily. For some complicated machines, we will send

engineer to your country to help installation

and training. But there will be extra cost for Engineer, including

the salary, visa cost, round-trip ticket

cost, and accommodation fee will be covered by the buyer.